ProfitFab v27

F9

Many tables have had changes made to the structure of the layout. Some have new fields added, others have been sized differently. When you open tables, hitting the F9 key on your keyboard will set the table to its default settings, which might make the new information visible for you, or correct the table if it is displaying the incorrect information due to structure changes. Remember the F9 key. It is your friend.

Program Enhancements

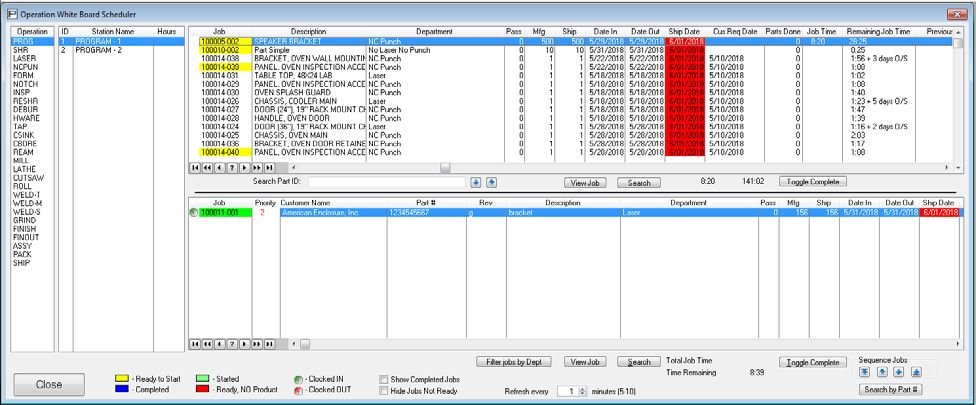

The Operation Whiteboard Scheduler

The Operation Whiteboard Scheduler has been redesigned to provide more scheduling capabilities. You can now use it to schedule jobs to specific stations, and keep track of how many hours are scheduled to each station.

Write your the content of your first column here. You can add shortcodes and html here. Write your the content of your second column here. You can add shortcodes and html here. Write your the content of your third column here. You can add shortcodes and html here. The structure of the Operation Scheduler is shown above. The table to the left displays all operations that can be put on part definitions. The second table displays all stations that are visible to the scheduler for the operation that is selected. The top job table displays all jobs for the selected operation that have not yet been scheduled. The bottom job table displays all jobs that are currently scheduled to the selected station. Information to help you make decisions on how to schedule work through the shop has been added. Each record displays the amount of time needed for the job at the selected operation, and this is used to provide a total amount of time for all jobs at that operation, displayed just under the job tables. The total under the bottom job table represents how much time you have scheduled at that station, and this value is also shown in the station table, so you can see at a glance the loading on all stations for that operation. Each record also displays the amount of time remaining on each job at all operations beyond the currently select operation. If a job contains an outside service beyond the currently selected operation, the lead-time days are also shown so that you can plan accordingly. Please note that in computing both of these time fields, we are not taking into account the setup time. This is based on per part times only.

In addition to these new columns, there are columns displaying Date In and Date Out. These dates are assigned by running the JIT Scheduler and they represent the latest possible date at which the job can be started or completed at the current operation and still be finished by the Scheduled Ship Date. The JIT Scheduler is described below. To schedule a job to a station, drag and drop from the top table to the bottom table, and then sequence the jobs as desired using the blue arrow buttons. The Operation Scheduler is visible at the shop clock module so that employees can view the work assigned to them.

Because the new Operation Scheduler is usually dealing with a large amount of data, it does not automatically refresh in real time. There is a Refresh timer at the bottom in which you can set it to refresh data every 5 – 10 minutes. Depending on the amount of data you are dealing with (some shops may have 250-500 active jobs while other shops have 2500-5000 active jobs) and the time it takes to process this data, you should set this value so that it does not spend all of its time refreshing the screen. If you are using Departments to differentiate work in your shop, you can filter the table by department to show only certain jobs.

JIT Scheduler

The JIT Scheduler is a new scheduler added to the program to provide very specific information, primarily for the Operation Scheduler. It is based on the Station Scheduler that has always been in the program, so it takes into account things like Global Lead/Trail times, lead times on services and materials, and the capacity of stations with regard to their calendars. The main difference between the Station Scheduler and the new JIT Scheduler is that the JIT Scheduler runs each job as if it were the only job being scheduled. Whereas the Station Scheduler will start to fill up holes in your capacity with jobs being scheduled so that jobs being scheduled last have fewer holes of time available to them, the JIT Scheduler will always find exactly the time it needs to get each job done in exactly the amount of time it needs to finish before the Scheduled Ship Date.

Also, where the Station Scheduler is designed to not go into the past when it schedules, the JIT Scheduler will go into the past and still schedule the same way. What this does, in effect, is that if you do not change the Scheduled Ship Date of a job, or any of the job properties that dictate the amount of time needed, then you will always get the same results for the job whenever the JIT Scheduler is run. The main purpose for the JIT Scheduler is to define event dates for each job for Scheduled Start date, 1st Operation Start date, and Last Operation End date, and to assign to each operation on the job a Date In and Date Out. These dates are an absolute best case scenario of working the job JIT to meet the Scheduled Ship Date. The Date In/Out of each operation is used in the Operation Scheduler to help determine the order in which you want to manually schedule jobs on the floor. The JIT Scheduler will automatically run when you verify an order. You can also manually run it for all jobs from the Schedule pull-down menu in the program.

Report Previewer

We are using a new report previewer so that when you print reports to the screen you can mark individual pages to send to a printer.

Route Package

We have added a Route Package checkbox to the Part Related Files form. You can use this checkbox to select files you want to print for each job of that part. The Order Form has a checkbox for printing the Route Package. When using this feature, the program will loop through all the part related files to find the ones that are designated as part of the Route Package, and will open them in the default program associated with their file type. Please keep in mind that we are unable to automatically send those files directly to a printer. That has to be done within whatever program you use to open those files with. We will open the files for you so that you can then print them from their default program without having to open them manually, one at a time, and then print them.

If you use this feature, be aware that you might run into problems if you create an order that results in many instances of files needing to be opened, such as jobs for large assemblies that generate 100’s of subcomponent jobs, each with its own route package. Opening too many windows could cause your PC to run out memory and freeze or slow down considerably.

Part # and Product ID size changes

The size of Part #’s and Product ID’s has been increased to 40 characters. The Shop Code and Source ID fields have also been increased to 40 characters. This is a major change to much of the program and will require you to make some changes to take full advantage of this. First, many of the tables that display the Part # or Product ID need to be reset to show the full amount. This is one of the places where you would open the table and use the F9 key to reset the table, as described at the beginning of this document. You will also need to go into the Report Designer to increase the size of the fields on your layouts if you intend to use longer #’s and ID’s.

To make changes in the Report Designer:

- Open layout to be changed

- Select field by single-clicking it. You should see the little red boxes surrounding the field when it is selected.

- Either right-click and choose Control Properties, or hit Enter Key to bring up the Control Properties dialog.

- In the Format field, you define the picture of the data. For an alphanumeric string, this format is “@S” followed by a number to represent how many characters to display. They should all be currently set to “@S20” to allow them to display 20 characters. You need to change this number to the size you want to display. When setting this up, please consider how many characters you will actually use. Shops asking for a larger field have mentioned needing anywhere from 24-30 characters. If you never anticipate needing more than, say, 24 characters, you should only set the fields in the report layout to “@S24”. The reason for this is that reports like the Quote, Order Acknowledgement, Invoice, etc., only have so much room to work with left to right. If you try to make the field larger than you need, you will probably have to also move other fields around to make room for it. If you never use all 10 characters available to the Revision field, you can decrease the field size on it in your layouts from 10 down to 1 or 2 or how many you actually need. You will also need to adjust any bar code fields that contain this data.

The following is a list of all layouts that contain the fields that have been changed

Active Job Listing

Active Job Status Listing

Assembly Completion Report

Blanket Order

Blanket Order Acknowledgement

Blanket Order History

Certificate

Completion Report Simple Part

Completion Report Summary

Customer Active Job Status

Customer Parts Costing

Customer Parts Listing

Customer Parts Physical Listing

Customer Parts Remfg List

Customer Parts Shipped Detail

Detailed Purchase Order

In House Product Reorder List

Inventory Sales History

Invoice

Invoice Ship Detail

Invoice Verified Detail

Invoice Working Detail

Invoice on Preprinted Paper

Job Completion Listing

Job Forecast Listing

Job Label

Job Time Detail

MRP Forecast Listing

MRP Start Date Listing

MRP Vendor Listing

Nest Job Search

Nest Route Sheet

Off Scheduled Jobs

Off Scheduled Jobs (Production)

On Time – Late Ship Report

Open Purchase Orders

Operation Detail Time

Operation Link to Parts

Operation Schedule (Infinite)

Order

Order Ack. on Preprint

Order Acknowledgment

Order Estimation Report

Order Time Detail

PO Material Tag

Packing Slip

Packing Slip on Preprinted Paper

Part Activity

Part Label

Parts Done

Parts Report

Physical Product Bin Worksheet

Physical Product Category

Product Cost Listing

Product History

Product Label

Product Listings

Product Reorder Listing

Product/Finish Link to Parts

Purchase Order

Purchase Order Delivery

Purchase Order on Preprint

Purchase Requisition

Quote

Quote Estimation Report

Quote on Preprinted Paper

RMA Form

Receiving Form

Request for Quote

Route Sheet

Scheduled Purchases Report

Scheduled Shipment Listing

Scrap Report

Service Link to Parts

Service P.O. on Preprint Paper

Service PO Packing List

Service Purchase Order

Service Receiving Form

Service Vendor On Time

Station Schedule

Vendor Invoice Register

Vendor NCM Form

Vendor Product Listing

Vendor Purchase History

WIP Report

Work In Process Report

Work Order Schedule

Vendor Categories

You can set up to four categories to classify a vendor’s status. In the System Setup under the PO & Inventory tab, you define the category. Three of the categories come with a color-coding of blue, yellow, or green, and one category has no color code. On the Vendor Form, you select which category the vendor is. Vendors that have one of the color-coded categories will show up in all tables with the Vendor Name displayed in the color of their category.

Miscellaneous

- Putting Orders on hold – for customer orders, a check box will allow you to put orders on hold. This does not affect the order in any way, but it will make the order record show up in yellow highlight in both the Customer Activity Center and in the Company Order Table so that it sticks out from all other orders.

- Verifying Purchase Orders – a checkbox has been added for security to allow users to verify PO’s

- Verified Orders – more fields have been opened on verified orders to allow you to make changes without unverifying them. You can now change the billing address, the shipping address, the PO#, and the line item quantity. Being able to change these fields will allow invoices made from the order to reflect the changes automatically so you don’t have to manually change the invoice after it has been created. With regards to changing the order quantity, if you are changing an assembly order quantity, you will need to make the change, close the line item, and then reopen the line item so that quantity changes are made to all of the subcomponents of the assembly.

- Dashboard can be opened in the Shop Clock module for employees to see who and what is where.

- Modified the Job Part Related Files to give a description of what happens when you attach files from the job and that they won’t show up at any other jobs for the same part, even though they still show up under the part definition. This was causing confusion for users who would attach parts at the job and then not know why they weren’t showing up at other jobs. The idea behind attaching parts at a job is that the files pertain only to that job, and not any other job. There is now also a checkbox to override this when attaching a file to a job that will let it be global to the part and show up at all other jobs for that part. The Part Related Files Table at the part definition also now has a column showing if files are attached to a single job (use the F9 key if you don’t see this column in the table)

- Alert Notes on jobs and routing will now be triggered to display when using the Nest Clock

- A warning message will be displayed if the line item on a PO does not meet the vendor minimum order quantity

- When shipping a job that still has MRP requirements that haven’t been satisfied, the program will now mark those items as Pull From Onhand so that they remain part of the job record. Previously, any unallocated MRP records would be deleted when the job ships, and the job history would no longer contain that information. If you unship a job, all MRP that had been marked Pull From Onhand will be unmarked and will go back into MRP and need to be dealt with.

- Added the Ship Via field to the Order Schedule setup so that you could alter that from the default setting on all the jobs coming from that order, instead of having to change the jobs one at a time after they are created.

- Added the Nest # field to the MRP Process table (use the F9 key)

- Added an additional user printer setup for Packing Labels, to allow it to differentiate between those and regular labels, as they tend to be different in the first place. You will need all users who print packing labels to go into their User Form and set this printer setting.

- Added a checkbox on the System Setup to make the Department field on part definitions a required field. If you are using departments, this will ensure that all new parts will have the department field set. It will not force currently existing part definitions to have a department set, unless you open that part definition again, at which time it will then require it to be set.

- Added a default shipping address tied to the vendor. If you have multiple shipping addresses and some vendors will always ship to a specific one, this will allow you to set that address for the vendor so that you do not have to change it each time you make a PO to them.

- A checkbox on user security has been added to allow them to update part definitions if they make changes on the job part definition. Currently, this is set to only allow changes if the user has the security to edit part definitions, but now you can set it so that it will not allow them to change the master part definition no matter what changes they make on the job.

- Reformatted the time fields on the Part Routing Forms to have individual fields for Hours, Minutes, and Seconds, and added a field in the System Setup to allow users to choose Seconds with 0, 1, or 2 decimal places. This change might cause you to need to make modifications to some layouts in the Report Designer, specifically to any layouts that print the routing times and the data does not appear to print out correctly.

Reports

Service PO Packing List and Packing Labels

There are new reports for Service PO’s: a Packing List and Packing Labels. The Packing Labels work similarly to the Customer Packing Labels. You will need to import the default layouts into the Report Designer to use these new reports. To add the new layouts to the Report Designer, follow these steps.

Quote Estimation Report in Excel

A new estimation tool for quotes has been added in the Quote Form. This report will put the detail from the Quote Estimation Report into Excel. For assemblies, the data will be combined for the entire assembly so that you can see the totals of labor operations and materials used on the quote.

Miscellaneous

- You can now print a Certificate of Compliance/Conformance from the Company Job Activity Table, and not have to wait for a job to be shipped to print it.

- Added Excel output options on all Red Flag reports

- Added bar code fields to the Packing List report. Bar code fields are the same as what is available on the Packing Labels.

- Customer Alert will now be triggered when printing a Packing List during the shipping of the job, and not just when you print the Packing List from within the invoice.

- Added new fields to various reports. To get new fields on to a layout, you will need to go into the Report Designer and add the fields, as we cannot overwrite your layout file without losing all changes you might have made in the past. WIP (Jobs) report now takes into account assembly components on job before the parent operation is marked complete. Before, the parent operation where components were attached had to be completed before we added the cost of the subcomponents back into on job portion of WIP. Now, if the operation is not complete, we will use the sum of the Part Count from time records to determine how many subcomponents to add to the on job WIP value.

- Route Sheet – fixed problems where the material field for structural material was printing the part costing size + webbing size, and where assembly components that had been removed from the job initially were not printing in the assembly component band as being needed.

- On Time Shipping Report can now be based on either the Scheduled Ship Date or the Customer Requested Date

Problems Fixed

- Fixed a problem where deleting a part definition from Customer Activity Center, or a PO from the PO Table would cause the tables to get out of sync, forcing the need to press F9 to restore their defaults

- Fixed problem where the Nest clock would let you clock out of a nest even if it wasn’t clocked in

- Fixed problem with Dashboard that caused it to get stuck in infinite loop because of nested jobs

- Fixed problem where relational integrity would cause the deletion of all contacts for a customer/vendor.